With increased fines for ecological damage and for the safe-keeping of the environment, it is imperative for oil and gas companies to uphold the highest level of quality, record keeping and traceability of data. Using highly accurate, reliable and easy to use metrology systems is essential in these industries.

Fowler High Precision has a product offering for the Oil & Gas and Energy sectors which provide measurement solutions for a variety of specific applications including:

• Measurement of external dovetail slot with ball contacts • Internal diameters inside seat pockets

• Internal spot face distance between flats

• Internal spot face to diameter measurement

The Fowler Bowers Solutions

Fowler XT Groove Gage the Best Way to Measure Internal Groove Diameters

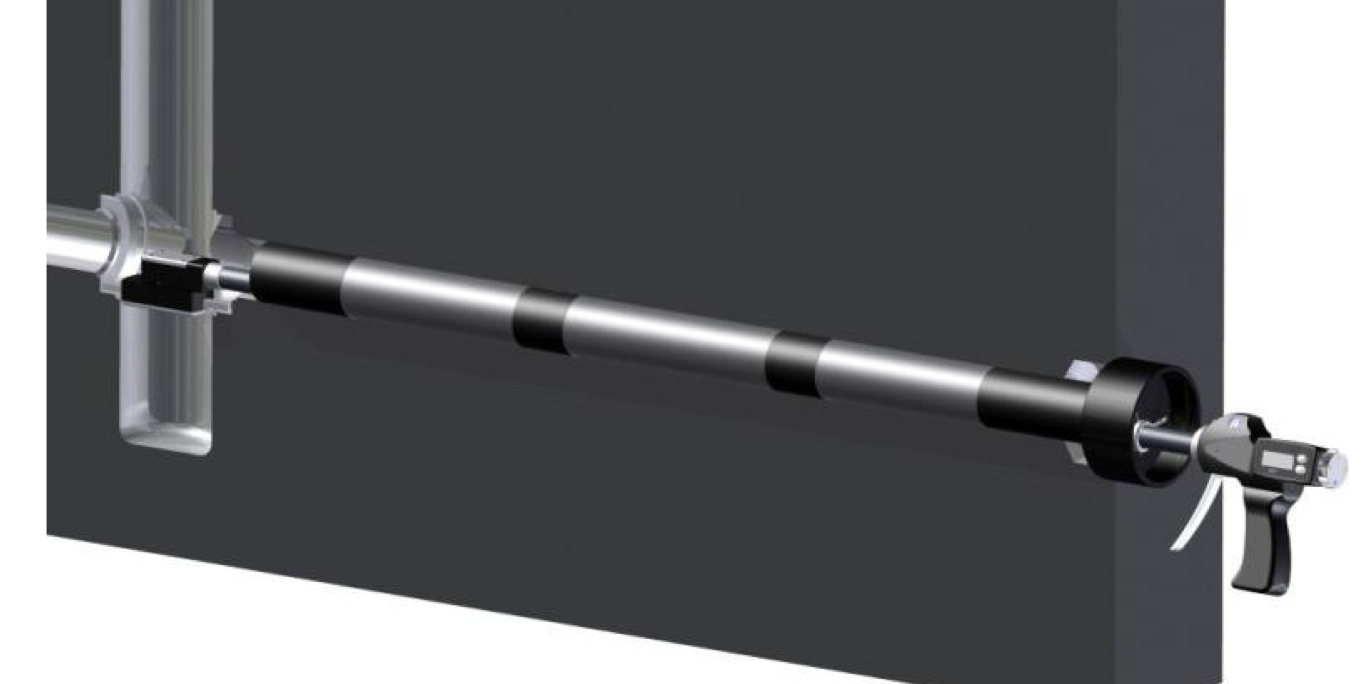

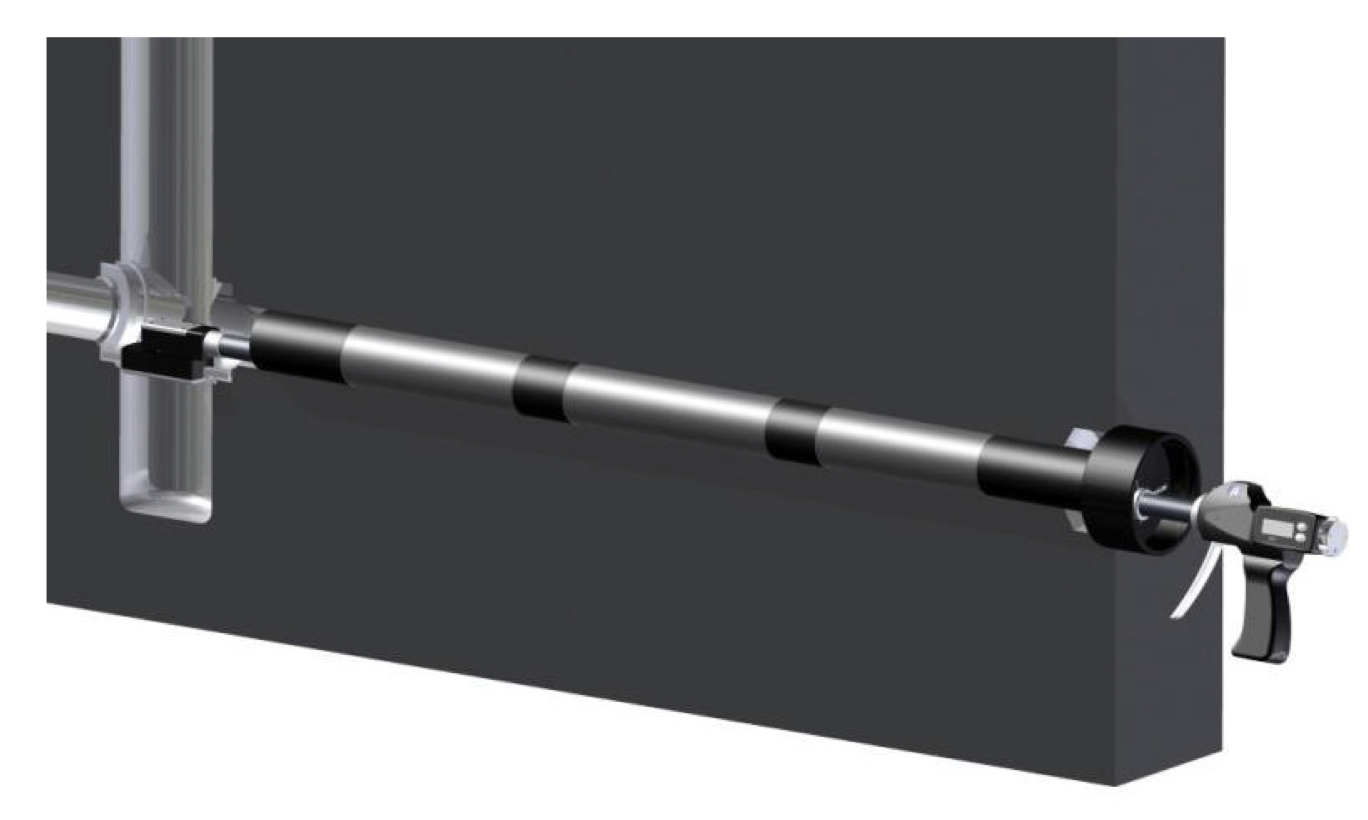

The Fowler XT Groove sets are based on the standard, self-aligning, 3-point XT head design, but with a stepped anvil to allow entry into grooves for fast and repeatable groove

diameter measurements.

The trigger action pistol-grip controller enables the operator to retract the anvil

instantly and pass the gage through the entry diameter, then extend the anvils to engage with the groove diameter for an immediate absolute measurement.

Fowler Valve Cavity-Seat Pocket Gage

Bowers developed a solution for Fowler utilizing a one-piece right angle adapter to allow entry down a perpendicular bore, allowing measurements to take place at 90 degrees to the entry of the bore. An optimized anvil form and guide piece aid entry and position the measuring head correctly for higher accuracy measurements and ease of use.

Fowler Dovetail Slot Gage

Bowers’ Special Applications Team developed a special

2 point head solution incorporating tungsten carbide ball contacts for high accuracy. The digital readout with standard Bluetooth capability offers the user to wirelessly send data to a computer or tablet for SPC evaluation and part traceability.