The Postle Hardbanding Gauge is a patented tool designed to assist in hardbanding and drill pipe inspection operations. It allows the hardbander, or inspector to quickly look at hardbanding to determine if re-application should be considered. It is also used to inspect new hardbands to determine if the bands were done in accordance with acceptable specifications. Another feature of the gauge is it provides a quick reference for torch stick out for applicators to use to help speed up their work and ensure consistent and proper torch height.

On one side of the gauge, the measurements and dimensions are in Metric units, and on the other side they are in Imperial units.

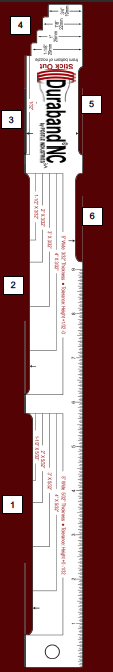

The following are the key features of the gauge which can be cross referenced on the graphic to the left.

1) 5/32” (4 mm) profile – This is for measuring the maximum hardbanding height of new bands. For bands prouder than 5/32” (4 mm), the pipe owner should be consulted. It’s important to keep in mind that prouder bands could create clearance problems.

2) 3/32” (2.4 mm) profile – The 3/32” (2.4 mm) profile is for measuring the minimum

hardbanding height of new bands. Bands too low could create a problem in extremely

abrasive situations and hardbanding could wear flush more quickly.

3) 1/32” (0.8 mm) profile – This is for measuring the height of old bands. Anything less than 1/32” (0.8 mm) should be re-hardbanded. Re-hardbanding old bands higher than 1/8” could result in bands unacceptably proud. In extreme situations, pipe owner might elect to rehardband before 1/32” (0.8 mm) is reached, to not experience tool joint wear if the hardbands were to wear off before the next scheduled maintenance.

4) Torch stick out notches – These notches are for use by the hardbander to position the torch height. They are a quick and easy reference to ensure adequate and repeatable torch height

5) Smaller 3/32” (2.4 mm) profile – This is a new feature on the gauge and is for minimum

hardbanding height on new tubing hardbanding applications.

6) Smaller 5/32” (4 mm) profile – Again this smaller notch is a new feature of the hardbanding gauge and indicates the maximum hardbanding height on new tubing applications.

It should be noted that recently the maximum acceptable hardbanding height has changed from 3/32” +/- 1/32”, to 5/32” + 0” and – 1/32”.

The straight edge of the gauge can be used to easily check the profile of the new bands. Remember that either flat or slightly domed bands are preferred, and concave bands are never acceptable.