We have developed several processes that can improve welding and wear performance utilizing CMT Technology

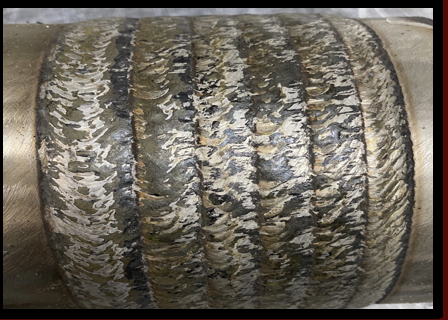

The above photo shows the CMT process utilizing Postle’s Tubeweld NCMT to rebuild the O.D. of tubing upsets.

The above photo is of the CMT process utilizing Postle’s Ultraband NM to protect non-mag tools.

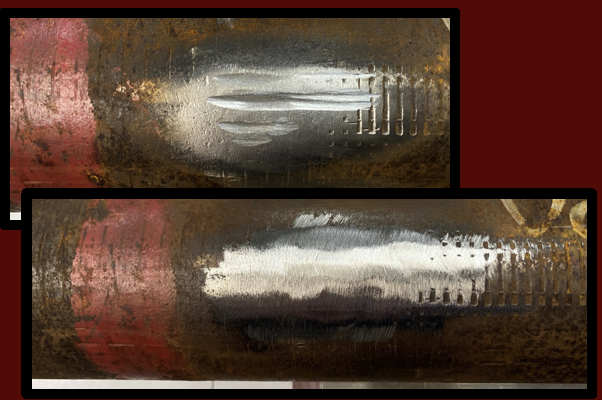

The above photos are of slip cuts that have been prepped for welding and then of the CMT process welded and ground flush for the completed repair.

In many industries, newer forms of welding technology have made

advancements in material capabilities that previously weren’t possible.

For over 2 years, Postle Industries has been evaluating these welding

technologies and conducting a comprehensive evaluation to determine

what advantages may exist for oil & gas drilling tools and wear

protection. Our conclusion is that CMT (Cold Metal Transfer) welding

technology can offer significant benefits. In this bulletin, we won’t be

able to delve into the welding technology of CMT, but can give an

overview of its benefits and what it can offer to wear protection.

Benefits of the CMT welding process:

• Lower welding heat – this means that welding can be done on

thinner materials without significantly harming the integrity of

the welded part

• Less Dilution – due to lower heat, less of the parent material is

melted and therefore doesn’t dilute the weld puddle like

conventional welding

• Higher Deposition – again, due to the advanced technology of

CMT the weld material deposition rate is increased

The advancements in CMT along with the innovation that Postle has

been able to realize with the equipment has been made possible

through the development of a synergic line that operates the CMT

equipment. This synergic line was developed specifically for Postle

and works well with Duraband along with our other metal cored wires

for oil & gas procedures.

There are several procedures that have been developed by Postle that

utilize CMT welding equipment and Postle’s synergic line which

include:

• Rebuilding of tubing upsets utilizing Postle’s Tubeweld NCMT

wire developed for this specific application

• Hardfacing non-mag tools utilizing our Ultraband NM wire

• Repair of tubing slip-cuts with Tubeweld NCMT

These procedures existed previously with conventional welding, but

have been modified and improved due to the weld control that is

possible with CMT.

We are able to provide CMT welding capabilities on our SKYE

hardbanding equipment or provide equipment to retrofit an existing

unit.