Manufacturing medical implants: from powder to full part certification, discover Renishaw’s end-to-end AM process chain

Medical device requirements

- Complex conformal design involving a lattice structure for osseointegration and faster patient recovery time

- Opportunity to manufacture using materials such as titanium alloys, which are difficult to produce using traditional investment casting techniques

- Traceable process information from powder to full-part certification

- Exceptional implant functionality and high-quality aesthetic results

The total AM process chain

Manufacturing medical implants: from powder to full part certification, discover Renishaw’s end-to-end AM process chain

Medical device requirements

- Complex conformal design involving a lattice structure for osseointegration and faster patient recovery time

- Opportunity to manufacture using materials such as titanium alloys, which are difficult to produce using traditional investment casting techniques

- Traceable process information from powder to full part certification

- Exceptional implant functionality and high-quality aesthetic results

AM for medical applications

Changing lifestyles and increased life expectancy will see global demand for orthopaedic implants increase significantly over the next decade or so.

Traditional orthopaedic implants are made from cobalt chrome or titanium, which have a higher tensile strength than the surrounding bone. However, titanium alloy implants are difficult to produce using traditional investment casting.

By contrast, additive manufacturing (AM) offers the design freedom to produce intricate freeform components in materials such as titanium, which are lighter in weight, higher performing, faster to build, more cost‑effective and better adapted to their application than direct replacements or adapted designs. Using AM for medical applications can speed up patient recovery time and extend the life of an implant.

Did you know that Renishaw is the only company in the metal 3D printing industry to offer the technologies and expertise that provide both highly productive metal 3D printing and control of finishing and downstream processes?

Discover the end-to-end journey of a tibial tray component, from design and build using our world-leading AM technologies, to subsequent downstream machining, finishing and safety-critical final inspection.

The tibial tray component

The tibial tray is one of a series of parts that comprises the artificial implant used in total knee-replacement surgery. Damaged bone and cartilage are removed and replaced with metal components that re-create the surface of the knee joint. The tibial tray is attached to the tibia (shinbone) and supports the load-bearing upper part of the implant.

Osseointegration is the structural connection between the living bone and the implant. Achieving a strong bond between the growing bone and the implant is essential for the long-term stability of a prosthesis. Implants formed with surfaces that feature complex lattice structures can aid osseointegration. However, the conformal design of such structures cannot be manufactured using traditional CNC machining alone. The traditional method of near-net investment casting used to produce components made from bio-compatible metal alloys, is costly and manually intensive. Additive manufacturing can reduce the labour involvement required.

Design

By using AM to produce medical implants, it’s possible for orthopaedic surgeons to engage directly with the design process with the freedom to create patient-specific custom designs. Additively manufactured implants can reduce surgical impact and improve recovery times, for enhanced success rates.

Our QuantAM build-preparation software takes the output from third-party software packages and processes those designs as 3D models ready to print. The processing functionality of our QuantAM software can even be embedded into the third-party CAD/CAM environment, allowing you to perform topological optimisation and then design efficient structural supports.

Build

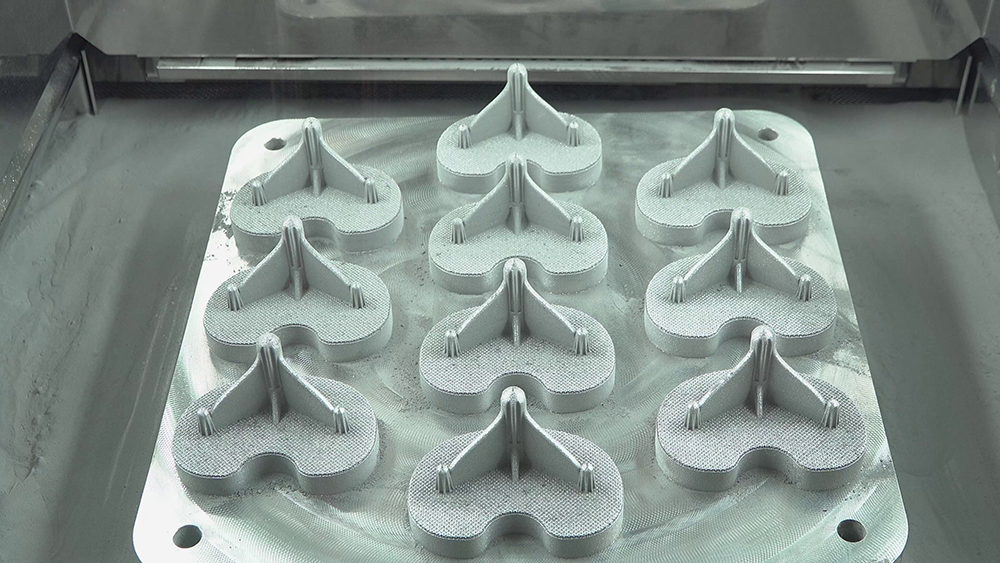

Once the tibial tray component and build process have been designed and validated using digital CAD software, a build-preparation file can be prepared offline and exported to the additive manufacturing system. In this example, ten tibial trays will be built on a single build plate.

As you’ll discover, we offer multiple technologies that surround our highly productive RenAM 500Q metal 3D printing system, and support efficient and cost-effective AM processes.

Our QuantAM build‑preparation software takes models generated in CAD/CAM and analysed and optimised with finite element analysis (FEA) tools and prepares them for build.

Our melt pool monitoring and analysis software, InfiniAM Spectral, provides feedback on energy input and emissions from the AM build process.

AM process data captured with InfiniAM Central is used for insight into live AM builds. AM machine and process information provides a record of individual builds, monitoring key parameters, alarms, and oxygen levels and so on. This data provides evidence for the performance and quality of each AM build, which can be used to verify the integrity of the metal structure from that build.

The RenAM 500Q AM system for ultra‑high productivity features four high‑power lasers. These lasers access the whole powder bed surface simultaneously for build rates up to four times faster than conventional single laser systems.

Our Equator™ gauging system allows you to validate the dimensional quality of built parts produced by the AM machine. This provides the confidence that you can move on to the next stage of the operation. Importantly, over time, the data gathered by the Equator gauge can be used by Renishaw Central for process control and to monitor drift or indicate machine maintenance intervals. This data can also be used to help optimise future AM builds.

Renishaw Central is the powerful manufacturing connectivity and data platform that enables you to build a complete end-to-end process for additive and subtractive manufacturing operations.

Machine

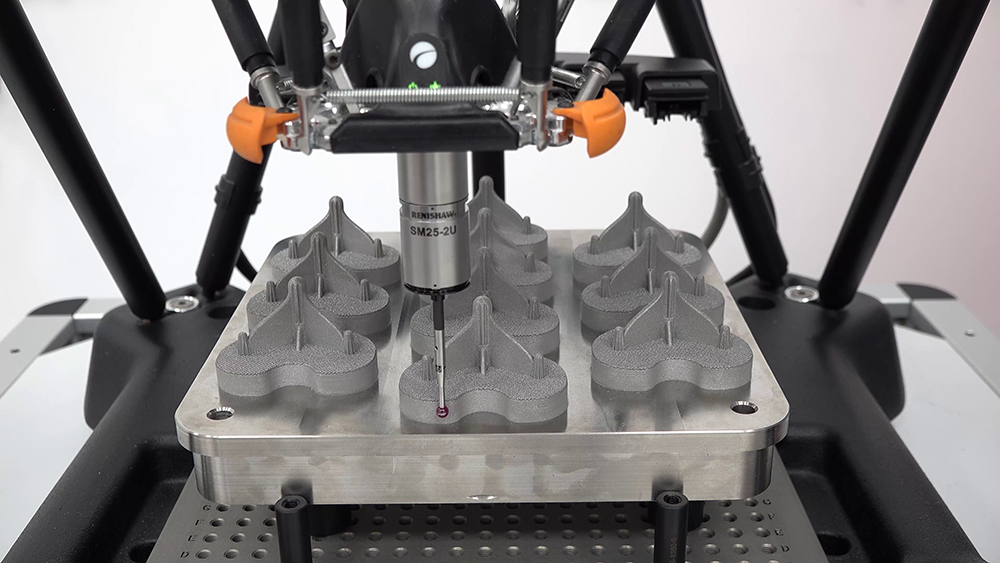

The build plate that comes off the AM machine features the ten AM-printed tibial tray structures ready for machining and finishing.

Stage one of the machining process involves machining the outer profiles of all ten tibial tray components while they’re still attached to the build plate. Before that machining process can begin, our NC4+ Blue non-contact tool setter is used to measure the tools and set the tool offsets. The NC4+ Blue offers high‑precision, high‑speed on‑machine tool measurement and broken tool detection.

Before profile machining, a Renishaw probing system is used to locate the position of the built parts to set local co-ordinate systems ensuring accuracy of the machining process.

Machining the outer profile provides a good interface for fixturing subsequent operations. Due to the fragile nature of these complex parts, this step is required before the next machining operation.

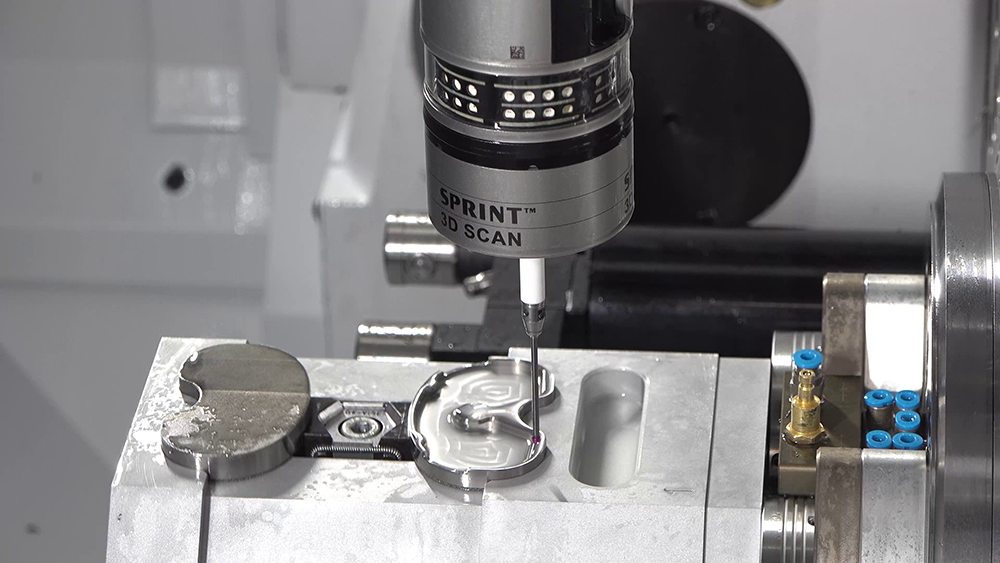

Stage two involves machining the tray features of the individual parts. Rapid on-machine probing using SPRINT™ technology quickly and precisely locates the machined features of the part relative to the position of the outer profile. With numerous individual parts held in a tombstone fixture, the machine can be left running for longer periods of time without manual intervention.

Medical devices, such as orthopaedic implants, must of course deliver exceptional performance functionality. In addition to this, parts manufactured for medical applications must have highly polished surfaces. To minimise polishing and processing time tool-to-tool blending is a critical consideration when machining faces and features with several tools. The NC4+ Blue tool setting system offers excellent tool-to-tool performance capability, which ensures reduced downstream processing and polishing time.

On-machine scanning using SPRINT technology is used again to capture surface features on the part for machining process control. The measurements are used to verify the machined features and update the tool offsets.

All measurement data is captured by Renishaw Central for visibility of machining process, which can be used to analyse process performance over time and verify whether you’re within control limits.

Stage two involves machining the tray features of the individual parts. Rapid on-machine probing using SPRINT™ technology quickly and precisely locates the machined features of the part relative to the position of the outer profile. With numerous individual parts held in a tombstone fixture, the machine can be left running for longer periods of time without manual intervention.

Medical devices, such as orthopaedic implants, must of course deliver exceptional performance functionality. In addition to this, parts manufactured for medical applications must have highly polished surfaces. To minimise polishing and processing time tool-to-tool blending is a critical consideration when machining faces and features with several tools. The NC4+ Blue tool setting system offers excellent tool-to-tool performance capability, which ensures reduced downstream processing and polishing time.

On-machine scanning using SPRINT technology is used again to capture surface features on the part for machining process control. The measurements are used to verify the machined features and update the tool offsets.

All measurement data is captured by Renishaw Central for visibility of machining process, which can be used to analyse process performance over time and verify whether you’re within control limits.

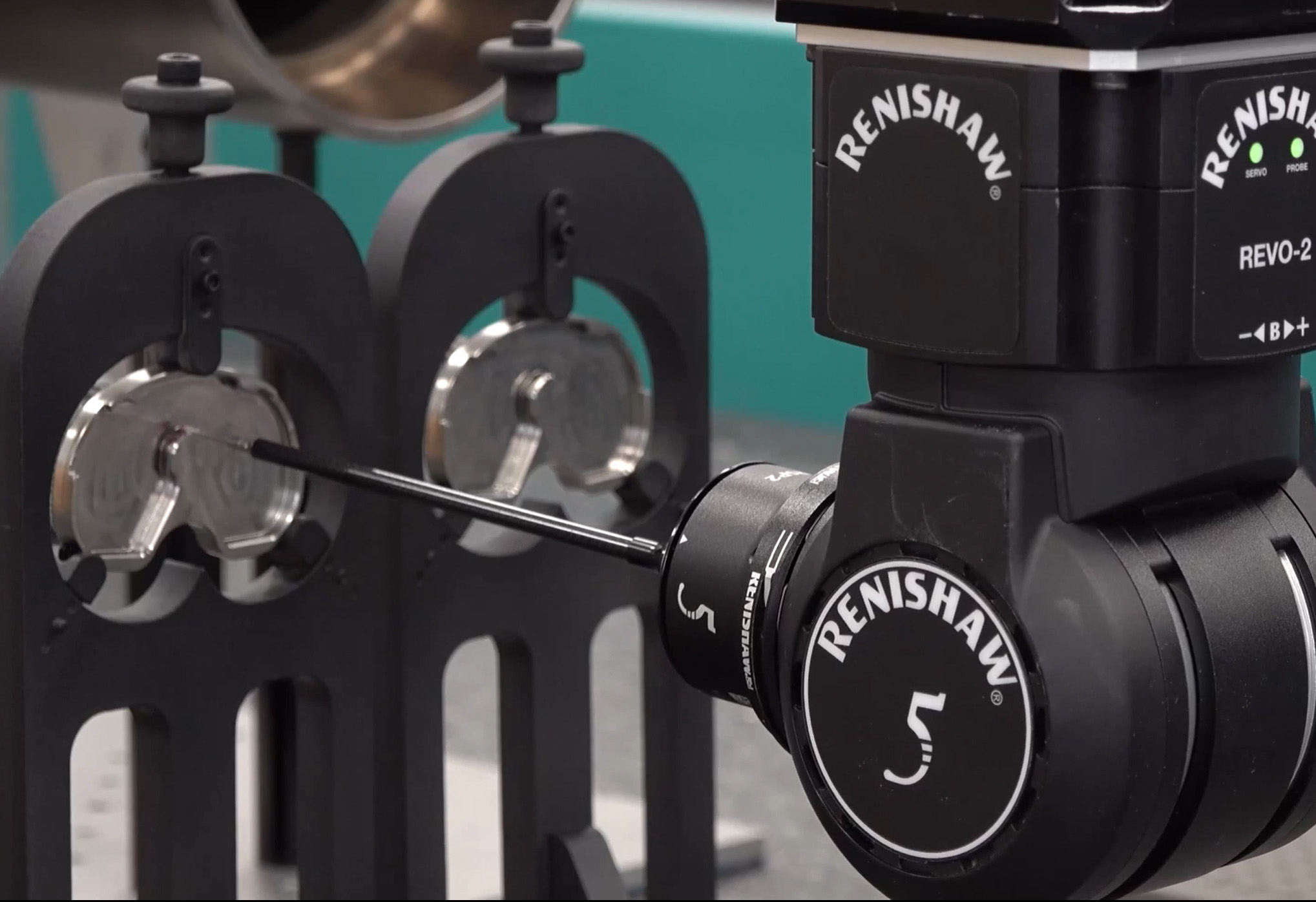

Part and process traceability

As the tibial tray component goes from CAD design to AM build, to freeform printed part and onwards for post-process machining and finishing, data is captured at each discrete production operation. Renishaw Central provides visibility of process and performance information and allows you to monitor the key parameters of all jobs and machining processes, which is used to examine process performance over time and make sure you’re within control limits.