Traditionally, hardbanding materials have been tested using the ASTM G65 abrasion wear test. This test can be performed on any alloy and lasts for a set number of revolutions of a rubber wheel, which forces dry sand against the test specimen. Weight is taken before and after the test to give a resulting volume loss. This measured weight loss can be used for comparing other materials put through the same test.

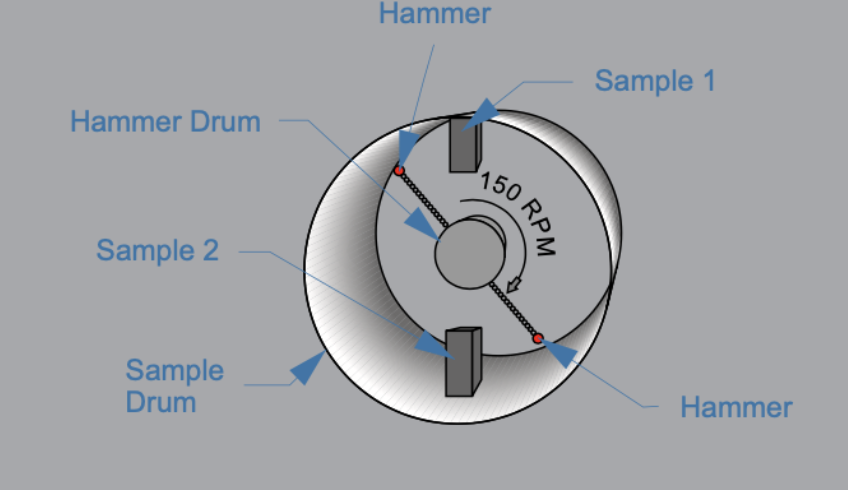

The G65 test is a reasonable indicator of abrasive wear resistance. However, the wear environment the drill string is subjected to downhole is far more complex. One factor the G65 doesn’t consider is impact wear. Imagine how many times and with how much force a tool joint will strike the casing or well bore wall during drilling operations. A good hardband must be tough as well as abrasion resistant. Impact resistance can be measured with the test apparatus shown below.

Schematic of Impact Test Apparatus

Tested against some well-known hardbanding brands, Duraband®NC showed between 40-60% superior impact resistance in third party testing.