Please contact your local Postle Representative or Technical Center for any information on proper weld parameters.

Managing the heat of the welding process is absolutely critical during the hardbanding procedure. Proper pre-heating and slow cooling will assist the weld metal and the base material (tool joint, tubing upset, or other downhole tool) through their metallurgical transition during the high heat and subsequent cooling process.

Pre-Heating

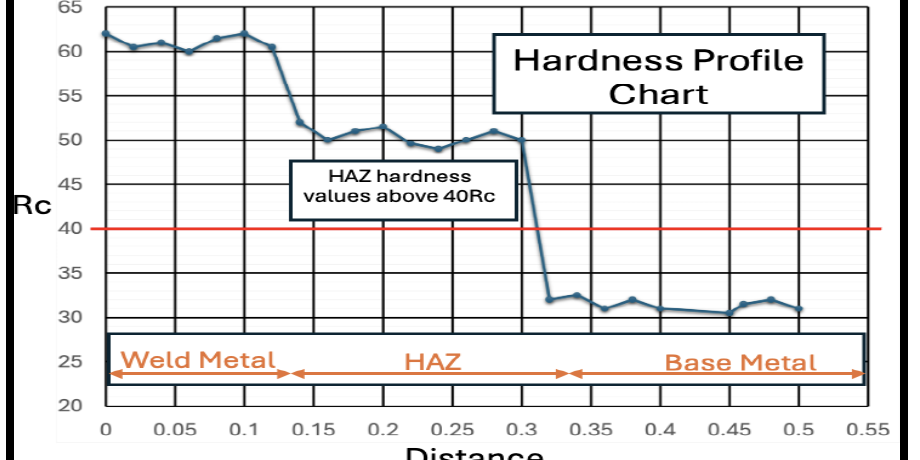

Pre-heating helps prevent cracks from occurring in the heat affected zone (HAZ), which is the zone directly below and adjacent to the weld bead. The HAZ is created as a result of the arc welding process and consists of the base metal, not the hardbanding alloy. This area cools most rapidly while undergoing important changes in its metallurgical structure and properties that may lead to cracking. The hardness of the HAZ is particularly important because if it is too hard, a crack in the hardbanding could potentially penetrate into the base metal and perhaps lead to failure of the connection. Typically, a hardness of 40 Rc is the maximum recommended in the HAZ region. In order to manage the hardness of the

HAZ, the pre-heat temperature should be adjusted in order to achieve an interpass temperature of approximately 800°F (430°C). The pre-heat must be a “soak heat” (see side column), meaning the heat has penetrated through the entire wall thickness. The interpass temperature is the temperature adjacent to the weld immediately after welding is concluded.

Pre-heating also minimizes shrinking stresses and enhances diffusion of hydrogen from the steel. Improper diffusion of hydrogen can lead to hydrogen embrittlement which can cause cracks.

Slow Cooling

It is imperative that the hardbanded tubular is immediately covered regardless of the temperature or weather conditions. We recommend keeping the hardbands covered to slow cool at an average rate of 50°/hour.

5 Key Points of Proper

Heat Management.

1) The proper pre-heat

temperature for drill pipe is

based upon the diameter of

the connection. Hardbanding

manufacturers

publish charts of pre-heat

temps. versus diameter.

2) Pre-heat temperatures

should reach a soak heat.

The soak heat temperature

is defined as no more than a

50° drop measured at the

surface of the heated area

over a period of 4 minutes

after the heat source is

removed.

3) Slow cooling can be

achieved by using cooling

cans, Hardbanding

Solutions Insulator Bags, or

other forms of insulation

material.

4) Inclement weather should

be avoided. Unless

preparations, welding and

cleanup take place in a

covered area, no welding

should be performed in rain,

freezing rain, snow, sleet, or

any weather that could

affect proper pre-heating or

slow cooling measures.

5) Controlling the HAZ

hardness values is critical to

the performance of the pipe,

tube, or downhole tool.