How to Compare Products Downhole

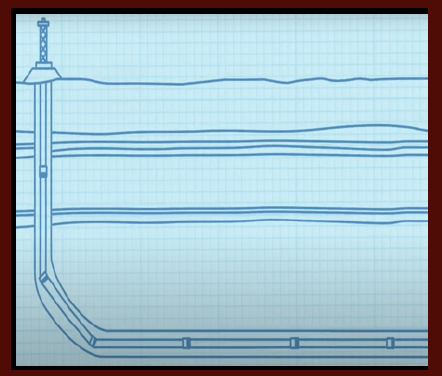

Laboratory testing such as the ASTM G65 wear test can give a good indication of an alloy’s performance. However, it will never accurately recreate the punishment that a hardband experiences downhole. Not only abrasive wear, but impact wear plays a big part, not to mention extreme temperatures, the effect of different mud types, etc.

When a downhole test is done to compare products, strict methodology must be

followed to ensure accurate results. For example:

• Products should be applied in the same place at the same time and measured to the same height.

• Products should be placed in adjacent stands in the string, at various locations, to experience the same conditions.

• All application and inspection should be performed by a neutral third party.

Comparing Hardbanding Products: The Devil is in the Details

At Hardbanding Solutions, we don’t get everything right all the time. However, we strive to learn and improve as we go. Sixteen years of manufacturing and promoting Duraband®NC has taught us more than a few valuable lessons.

One of the earliest things Hardbanding Solutions learned, and something we have stuck by ever since, was how to prove Duraband’s performance against competitive products. We have our own metallurgical laboratory which has performed hundreds of tests on

hardbanding alloys over the years to determine chemistry, wear resistance (abrasion and impact), weldability, crack-resistance and compatibility of reapplication.

Testing is done without any influence from management or sales, and results are never published. Testing of products that aren’t our own, are for our internal purposes only. That’s because we wouldn’t be considered unbiased, so to use internal tests to prove the advantages of Duraband over other products just isn’t right.

At the same time, any downhole testing we have initiated, or been invited to participate in, has and will be done fairly.

We learned never to publish incomplete or misleading information.

Duraband is often used by competitors as a comparison for their latest. product. We take it as a compliment and recognition of its success. However, be aware of promotional material without substance. We’ve seen graphs which don’t contain any quantitative data other than a bold claim about wear resistance. We ask our industry to demand the details. Where was testing done and by whom? What was the exact testing methodology that was used? Otherwise, as some have discovered when it’s too late, unsubstantiated claims can get costly downhole.

Finally, remember that wear resistance is only one property of any hardbanding wire. Duraband wear has been proven in every possible way over many years. It’s this combined with an extraordinary record of crack-free reliability, especially on reapplication, that means it continues to set the bar across the drilling world.