Description

Flexbar Corporation

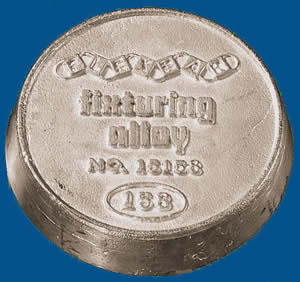

Fine Proofing Alloy, 1 LB Cake 117 Low Melt, Part #16117

FINE PROOFING ALLOY

KEYNOTE OF APPLICATIONS

Growth after casting is +.0002″ after 6 minutes.

However, after 30 minutes the change is .0000 (zero), so that this is the best time for removal and inspection.

After 1 hour and up to 21 days, the change is between .0001″ and .0002″ on the minus side.

USES: PROOFING VIA REPLICATION OF:

Dies – Moulds – Internal and External Thread Forms – Texture Check – Grooves-Slots – O-Ring Grooves – Gear Teeth – Splines – Surface Finish Replication – Extra-Fine Fixturing – Checking Undercuts

OTHER USES:

- Precision holding of irregular work pieces during machining.

- Dental-type model making.

- Drill bushings for drill jigs.

- Chucks for lens buffing – gem cutting.

- Transfer templates in contour jigs.

- Cores for electroforming.

- Compound wax patterns – lost wax patterns.

- Duplicating plastic. Facsimile or Plaster patterns.

- Fusible elements in safety devices and alarms.

- X-Ray (radio opaquing).

Fine Proofing Alloy can be used for Male to Female to Male or Female to Male to Female in conjunction with our Facsimile Measure-Image Replicating Material.

Steps: Make your first impression with No. 16117 alloy and let it cool down or accelerate cool down with water. Put oil or Release Agent on alloy replica. Dam off where necessary with plasticene or clay and mix Facsimile and pour into alloy replica.

Note: In some cases the configuration might call for reversing the procedure by taking first replica with “Facsimile” and then pouring No. 16117 alloy into Facsimile cavity. Obviously the configuration of the original would dictate which way to go.

Accordingly- you can clone or reproduce original parts for prototypes – small production runs, etc.

Instructions for Use:

Material melts at 117° F so that you can heat it in a small pot or ladle either over a burner or in a double boiler (pot in a hot water bath). Pot can be stainless, porcelain lined or cast iron. Aluminum, brass, or copper vessels are not recommended. Thermostatically controlled melting pots are good.

Procedure:

- No separator or release agent is required.

- Molten alloy solidifies quickly. This can be hastened by placing in cold water or by using a fan. Using cold water or a fan for cooling produces a fine crystalline structure which is better for inspecting the surface finish. As alloy is used at such a low temperature there is no danger of affecting the temper of the work piece.

- Replica is then removed for inspection or for recording purposes. Replica casting is strong enough to be shipped anywhere.

- Removal of the alloy is accomplished in hot water or with a steambath. Chips that float to the top of the molten alloy are removed by skimming, leaving the alloy sufficiently clean to be reused.

Note:

When checking molds:

- Block off vents with clay, tape or putty

- Create a reservoir barrier around the mold.

- Remove air pockets with a vacuum bell if available. Air bubbles may also be removed by puddling with a rod, as this will also permit molten alloy to flow into all areas.