Description

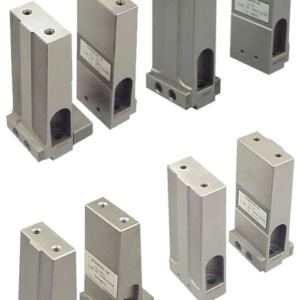

Gagemaker – BXG-1000 Face Groove Width Gage per API 6A

(.373″ to 1.500″ Ranges, unit ships with T.072″ Contact Points)

Get Fast, Accurate, Repeatable Readings Every Time…

Ensure Tighter Seals and Optimize Performance…

Take the Guesswork out of Inspecting Ring Grooves…

Gagemaker’s 6A Seal Ring Groove Inspection Gauge

Subsea equipment or wellhead and christmas tree equipment have pressure energized ring seal gaskets or more specifically ring grooves.

Not only do these seal gaskets require close tolerance inspection, the ring groove inspection on the flange is an API 6A requirement.

The Gagemaker Ring Groove Inspection Gages reliably and accurately inspect all the important elements: – Major Diameter, Minor Diameter, and Groove Width.

The system also offers groove width profiles and dog bone paddle gages as a dependable quick and easy receiving inspection.

The Minor Diameter is the INNER apex diameter of a seal ring groove.

This measurement is controlled during machining to adhere to standards and maintain required pressure rating.

The Major Diameter is the OUTER apex diameter of a seal ring groove.

This measurement is controlled during machining to adhere to standards and maintain required pressure rating.

Warranty: One Year from the date of purchase.

Long Form Calibration Report at extra charge from Houston Precision, Inc. at a 50% discount with new purchase.