Description

Connection Technology

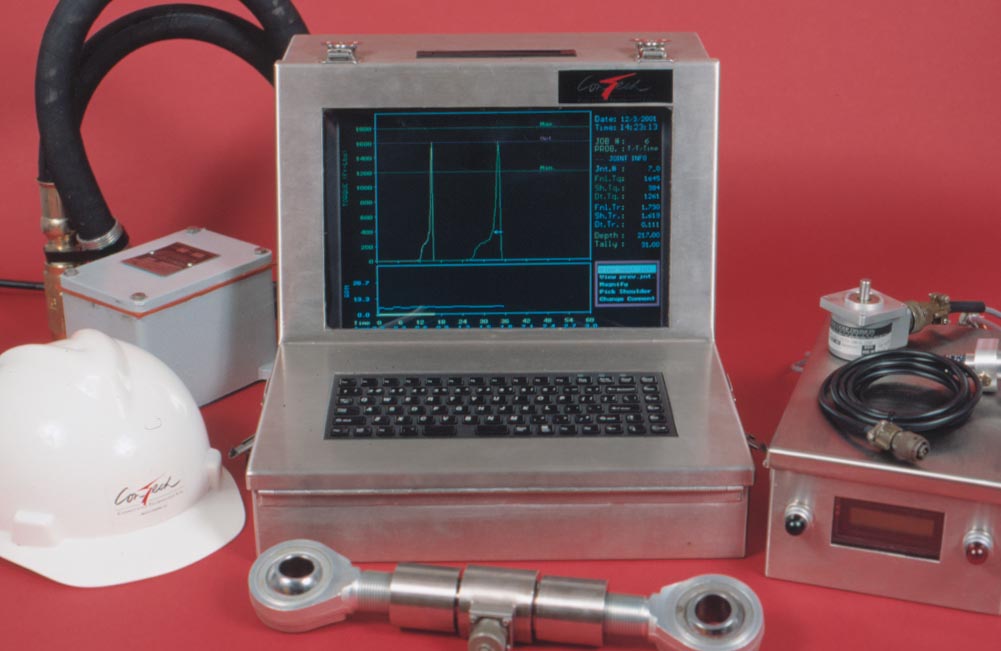

CT 3000 LT Torque Control System

ConTech’s Torque Control Systems are used in the makeup of casing, tubing, drill pipe, downhole motors and accessories, etc. ConTech’s Torque Turn Systems can be installed and run with virtually any hydraulic, pneumatic, or manual tongs in the field, as well as bucking units in plant applications.

The CT 3000LT Torque Turn System features high resolution graphics with two processors and a choice or four makeup programs, offered in both DOS and Windows based platforms. All PC hardware options are available in a unit that can be built to customer hardware specifications. Several “add-on” modules such as internal pressure testing, and accessories for hazardous area operations are available.

Software is “User Friendly” allowing shortened training for field technicians.

Hardware

- 110/220 Volt Switchable

- Color Monitor

- Display-Torque Digital in Real Time

- Display – Color Graphics in Real Time

- Electronic Dump Valve

- 35 Millisecond Dump Valve Response

- Electronic Load Cell

- Optional Hydraulic Load Cell & Pressure Transducer

- IBM Compatible

- Printing on-Site

- Real Time Clock

- Report – Hard Copy – Color Graphics

- 7 Day-a-week/24 Hour-a-day support for licensed customers

Software

- Data Storage Accomplished by Hard Disk

- Maximum Torque Input Value is 999,999 (ft/lbs.)

- Memory Storage capacity (in joints) in standard configuration is 2000(x100)

- Tong RPM graphed in real time

Programs available “Standard Package”

- Programs available in several languages, including Russion, chinese & Spanish

- Torque/Turn

- Torque/Time

- Torque/Turn/Time

- Double End Makeup

- dB Stat (Data Statistical Summary)

- Pressure Test “Add-on” Module

- Custom Programs Available

- ConTech “dB stat” Post Job Report

- Post Job Data exportable to other IBM Compatible Programs

Program Features “Standard Package”

- Joint Overlay

- Joint Re-Call (Instant)

- Magnification

- All Menu Features accessible @ Test Screen

- Menu Driven Programs with Direct Numeric Input

- Torque Shoulder Cursor Identifier

- Remote (modem) Diagnostics & File Transfer

- Sampling Frequency is 2,400 Data Points/Sec. in Standard Configuration

- Self Check Reliability Program

- 1/7500 Turn Resolution via Shaft Encoder

- Computer Networking

- PDF File Creation

To learn more about the CT 3000 LT Torque Control System, or to check pricing and availability, contact our sales department today.

Service: Contech offers to licensed customers worldwide, 24 hour-a-day/7 day-a-week hardware and software support