Description

Dorsey Metrology International

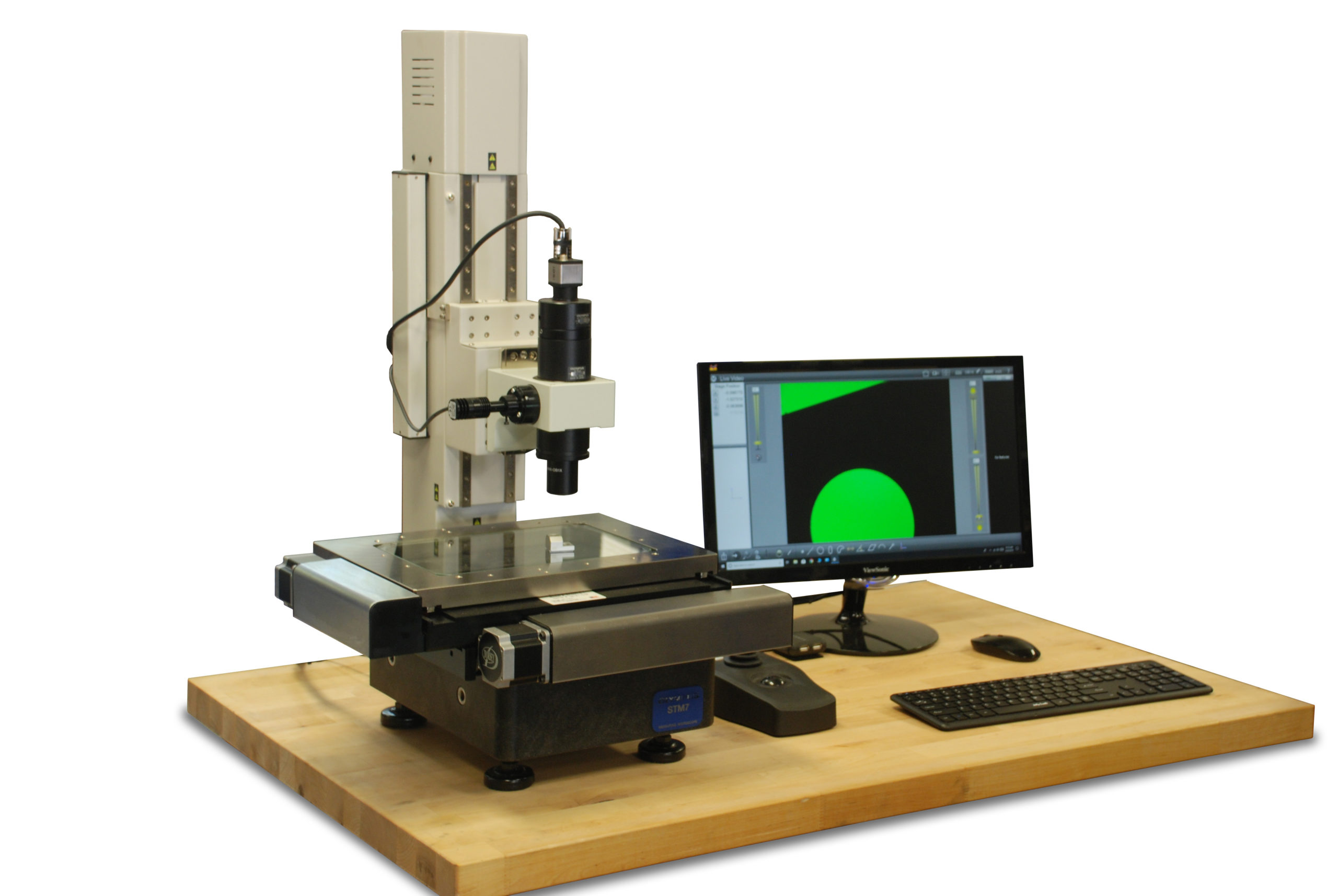

9100-CNC-M3 Series Video Inspection System updated design by DORSEY METROLOGY

The 9100 Series Video Inspection System is our largest heavy-duty model.

- Heavy-duty integrated granite base and column

- Large 12″ x 12″ travel stage

- High-resolution zoom optics

- LED profile and surface illumination

- Electronic crosshair generator

- 17″ LCD Flat Screen Monitor

- Z-axis measurements available

- Choice of Quadra-Chek and Metlogix DRO’s

- Optional Motorized Stage

- Optional 3-axis CNC Control

The 9700 Series Video Inspection System is our largest heavy-duty model.

- Heavy-duty integrated granite base and column

- Large 12″ x 12″ travel stage

- High-resolution zoom optics

- LED profile and surface illumination

- Electronic crosshair generator

- 17″ LCD Flat Screen Monitor

- Z-axis measurements available

- Choice of Quadra-Chek and Metlogix DRO’s

- Optional Motorized Stage

- Optional 3-axis CNC Control

Features/Options

- High Precision 12″ x 12″ travel measuring stages with .00005″/.001 mm resolution precision glass scales with quick release on X axis

- Heavy-duty granite base and column

- High-resolution 30X to 180X Par Focus Zoom Optics

- LED profile and surface illumination

- 17″ Flat Screen Color Monitor

- Digital crosshair generator with automatic edge indicator

- 6″ Focus travel with optional Z-axis measuring scales

- Choice of Quadra-Chek and Metlogix DRO’s

- Optional 2-axis or 3-axis Motor Controls

- Optional full CNC 3-axis Controls with Auto Focus, video edge detection, image capturing, and programmable lighting with joystick and trackball controls and fine-adjust knobs allowing movements to .00005″/.001 mm.

The 9700 Series Video Inspection System is our largest heavy-duty model.

- Heavy-duty integrated granite base and column

- Large 12″ x 12″ travel stage

- High-resolution zoom optics

- LED profile and surface illumination

- Electronic crosshair generator

- 17″ LCD Flat Screen Monitor

- Z-axis measurements available

- Choice of Quadra-Chek and Metlogix DRO’s

- Optional Motorized Stage

- Optional 3-axis CNC Control

Features/Options

- High Precision 12″ x 12″ travel measuring stages with .00005″/.001 mm resolution precision glass scales with quick release on X axis

- Heavy-duty granite base and column

- High-resolution 30X to 180X Par Focus Zoom Optics

- LED profile and surface illumination

- 17″ Flat Screen Color Monitor

- Digital crosshair generator with automatic edge indicator

- 6″ Focus travel with optional Z-axis measuring scales

- Choice of Quadra-Chek and Metlogix DRO’s

- Optional 2-axis or 3-axis Motor Controls

- Optional full CNC 3-axis Controls with Auto Focus, video edge detection, image capturing, and programmable lighting with joystick and trackball controls and fine-adjust knobs allowing movements to .00005″/.001 mm.

Specs

Work Table: 18″ x 18″ – Black Anodized

Measuring Range: (X)–12″ (Y)–12″ (Z)–6″

Allowable Work Load: 25 lb

Illumination: Profile – LED, Surface – LED

Magnification Lens: 30–180X Parfocal Zoom

Electrical: 100–240 V, 50/60 Hz Compatible

Weight (approx.):

| Manual | 455 lb Crated | 500 lb |

| CNC | 515 lb Crated | 560 lb |

Models

Video Inspection Systems (9700)

| Catalog # | Description |

|---|---|

| 20-9700-02 | 9700 with QC 220 DRO with 12″ X 12″ Travel Stage |

| 20-9700-33 | 9700 with M3 DRO with 12″ x 12″ Travel Stage |

| 20-9700-04 | 9700 with QC 5000 DRO with 12″ X 12″ Travel Stage |

| 20-9702-33 | 9700 with M3 DRO with 12″ x 18″ Travel Stage |

| 20-9702-04 | 9700 with QC 5000 DRO with 12″ X 18″ Travel Stage |

Extended Z Axis

| Catalog # | Description |

|---|---|

| 20-9718-00 | Optional 12″ Z Axis |

Motorized Stage Options

| Catalog # | Description |

|---|---|

| 20-9700-30 | X-Y Stepper Drive System with Joystick and Micro-Positioning Jog Controls for 12″ X 12″ Stage |

| 20-9702-30 | X-Y Stepper Drive System with Joystick and Micro-Positioning Jog Controls for 12″ X 18″ Stage |

| *20-9102-30 | Z-Axis Stepper Drive System with Joystick and Micro-Positioning Jog Controls for 6″ Travel |

| *20-9112-30 | Z-Axis Stepper Drive System with Joystick and Micro-Positioning Jog Controls for 12″ Travel |

*NOTE: The Z-Axis Option for the 9700 Requires the Purchase of the X-Y Stepper Drive System. These options are available with any DRO.

CNC Video Inspection System

CNC motor control options includes joystick control of stage motion and trackball for exact positioning.

Also includes Video Edge Detection and CNC motor control for automatic measurement.

Software includes auto-focus, auto light control, video edge tools and video overlay function.

M3 DRO provides easy to use programming control and fixed reporting capability.

Includes all feature types (point, line, circle, arc, distance, angle and skew), tolerancing and full feature graphic display.

QC5000 DRO is a PC based readout system with CAD-like user interface and unlimited feature and part program storage.

Features complete graphical part display and comprehensive reporting capability.

| Catalog # | Description |

|---|---|

| 20-9780-01 | CNC Video Inspection System with QC5000/12″ X 12″ Travel Stage |

| 20-9782-01 | CNC Video Inspection System with QC5000/12″ X 18″ Travel Stage |

| 20-9780-33 | CNC Video Inspection System with M3/12″ X 12″ Travel Stage |

| 20-9782-33 | CNC Video Inspection System with M3/12″ X 18″ Travel Stage |

| 20-9780-0112 | CNC Video Inspection System with QC5000/12″ X 12″ Travel Stage/12″ Z Axis |

| 20-9782-0112 | CNC Video Inspection System with QC5000/12″ X 18″ Travel Stage/12″ Z Axis |

| 20-9780-3312 | CNC Video Inspection System with M3/12″ X 12″ Travel Stage/12″ Z Axis |

| 20-9782-3312 | CNC Video Inspection System with M3/12″ X 18″ Travel Stage/12″ Z Axis |

Options and Accessories

| Catalog # | Description |

|---|---|

| 20-1413-00 | Console Stand |

| 20-1413-02 | Console base w/two arms and brackets for QC-220 and monitor |

| 20-1413-33 | Console base w/arm for M3 or QC5000 |

| 20-1413-35 | Console base w/articulating arm for M3 or QC5000/for 18″ travel stage |

| 20-1414-00 | Console base – 30″ high |

| 20-1415-00 | Computer desk |

| 20-4630-04 | Replacement Stage Glass (12″ X 12″ Stage) |

| 20-4630-05 | Replacement Stage Glass (12″ X 18″ Stage) |

| 20-4509-00 | Dust Cover – Replacement |

| 20-8614-12 | Datum Bar/Right Angle Plate for 12″ Travel Stage |

| 20-8614-18 | Datum Bar/Right Angle Plate for 18″ Travel Stage |

| 20-8614-21 | Fixture Adapter Plate for 12″ Travel Stage |

| 20-8614-22 | Fixture Adapter Plate for 18″ Travel Stage |

| *20-9120-05 | Measuring System for Standard 6″ (150MM) Z Axis |

| *20-9118-05 | Measuring System for Optional 12″ (300MM) Z Axis |

| 20-8626-00 | .5X Mag. Adapter Lens |

| 20-8627-00 | 2X Mag. Adapter Lens |

| 74-0500-00 | Stage Calibration Master 3″ x 6″, (75mm X 150MM) Cert. w/Wood Case |

*NOTE: These Items Must be Ordered at the Time of Purchase of a Video Inspection System.

Installation: We provide setup, installation, onsite calibration and training of your operators at your facitily.

Warranty: 2 year warranty on parts and labor.

Literature

Specs

Work Table: 18″ x 18″ – Black Anodized

Work Table: 18″ x 18″ – Black Anodized

Measuring Range: (X)–12″ (Y)–12″ (Z)–6″

Allowable Work Load: 25 lb

Illumination: Profile – LED, Surface – LED

Magnification Lens: 30–180X Parfocal Zoom

Electrical: 100–240 V, 50/60 Hz Compatible

Weight (approx.):

| Manual | 455 lb Crated | 500 lb |

| CNC | 515 lb Crated | 560 lb |

Literature

Features/Options

- High Precision 12″ x 12″ travel measuring stages with .00005″/.001 mm resolution precision glass scales with quick release on X axis

- Heavy-duty granite base and column

- High-resolution 30X to 180X Par Focus Zoom Optics

- LED profile and surface illumination

- 17″ Flat Screen Color Monitor

- Digital crosshair generator with automatic edge indicator

- 6″ Focus travel with optional Z-axis measuring scales

- Choice of Quadra-Chek and Metlogix DRO’s

- Optional 2-axis or 3-axis Motor Controls

- Optional full CNC 3-axis Controls with Auto Focus, video edge detection, image capturing, and programmable lighting with joystick and trackball controls and fine-adjust knobs allowing movements to .00005″/.001 mm.