Description

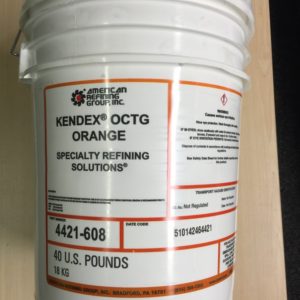

American Refining Group

Kendex OCTG Orange Corrosion Inhibitor, 55 GAL. Drum 412 lbs.

PRODUCT DESRIPTION:

A unique, thixotropic, grease-like corrosion inhibitor, Kendex OCTG Corrosion Inhibitor was developed and evaluated specifically for long-term rust protection of Oil Country Tubular Goods. The highly polar, microscopic platelets are parallel to the metal surface. These platelets form overlapping particle layers that function as a moisture barrier.

RECOMMENDED APPLICATION:

Apply Kendex OCTG to both the pin end and inside of the thread protector. All of the surfaces that are going to be protected by the Kendex OCTG should be clean (devoid of rust and dirt) and dry. It has been demonstrated that a small amount of Kendex OCTG inside the thread protector prior to screwing it on will push material forward giving better coverage to the nose of the pipe, covering the 45% chamfer and the flank area as well. The product is engineered with a low viscosity to easily allow one gallon of Kendex OCTG to cover approximately 160 sq. feet under optimum conditions or one liter of Kendex OCTG to cover approximately 3.39 sq. meters. A coating thickness between 1/32” and 1/16” applied uniformly over the desired surface will provide adequate protection.

PROPERTIES:

RUST PROTECTION – Prevents pipe thread rusting for over 2,000 hours of 5% salt fog cabinet testing when applied at a minimum 10-mil thickness.

SELF-HEALING – Ability to creep at least ½ inch after application protects areas not coated, or where coating was displaced.

MOISTURE DISPLACING – Will displace moisture to insure good bonding and rust protection.

THIXOTROPIC – Readily applied by brush or spray but resists sag, run-off or flow.

LUBRICANT – Minimizes thread damage during assembly and disassembly of threaded ends.

THERMALLY STABLE – Coating resists cracking, disbanding or run-off or flow.

ELECTRICALLY INSULATING – Resistivity of about 1015 ohm-cm reduces opportunity for galvanic corrosion. Resistivity, conductivity and dielectric constant values are comparable to those properties for the thermoplastic and thermosetting plastics evaluated.

MICROBE RESISTANT – Coating is resistant to attachment by sulfur reducers and other bacteria, which normally accelerates corrosion.

UV RESISTANT – Resists degradation from sunlight.

COMPATIBLE – Is compatible with petroleum-based solvents, oils and greases.

ADHESION TO RUST – Will bond to firm rust and reduce the rate of further rusting.

WELDABLE – Coating removal is not required before electric or gas welding, or for oxy-fuel cutting.

COATING REMOVAL – Hydrocarbon solvents or alkaline wash systems may be used for coating removal.

PACKAGING – Available in non –returnable 55 gallon drums – 412 lbs. net weight or in 5 gallon plastic pails 40 lbs. net weight.

APPROVALS – recommended for use by Hydril. See Report TU86-016A

PROPERTIES TYPICAL INSPECTION DATA

APPEARANCE ORANGE COLORED THIXOTROPIC LIQUID

% NON-VOLATILE 100

VISCOSITY, BROOKFIELD 20,000 CPS

#6 SPINDLE, 10 RPM, 77°F

RUST PROTECTION,

5% SALT FOG, ASTM B-117 OVER 2,000 HOURS

WATER DISPLACEMENT GOOD

DRIP OR RUN –OFF NONE BELOW 300°F

LOW TEMPERATURE ADHESION GOOD TO –40° F

FLASH POINT, ASTM D 92, °F 325

SPECIFIC GRAVITY @ 60°F 0.98

PREF. APPLICATION TECHNIQUE BRUSH AT 30°F to 100°F

SPRAY APPLICATION 50°F – 100°F

(271 AIRLESS SPRAY EQUIPMENT USING 0.018”