Description

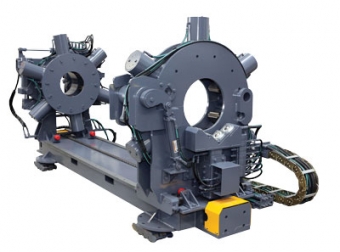

McCoy Global

weBUCK, 11-3/4″ Electric Powered Bucking Unit

Key Features

Health, Safety & Environment:

- Full or semi-automated operation minimizing risk to operators

- Quiet operation, less than 80 dB, meeting OSHA requirements

- Electrically operated, eliminating risk of hydraulic leakage.

Economics

- Configurable to communicate with any existing customer control system. Currently McCoy Global can accomodate Ethernet, PROFINET, Modbus TCP/IP, Profibus™, DeviceNet™ and CANopen™.

- The versatility of the designed control system and available I/O allow for a variety of customer system stopping and coupling thread engagement devices. For example, the system can work with hard-stop sensors, leading edge sensors, inferometers and LVDTs.

- The electrical drive greatly reduces maintenance cost over hydraulically powered units.

Ergonomic Control

- Optimized using a HMI/touchscreen operator interface on a console, equipped with electromechanical contingency switches for continued use in the unlikely event of a HMI failure.

- Equipped with onboard data logging, troubleshooting and diagnostics capability.

| Product Specs: | weBUCK™ 12 |

|---|---|

| Gripping Diameter | 2-3/8″ – 11-3/4″ (60 mm – 298 mm) |

| Maximum Passage Diameter Through Head | 13.84″ (351 mm) |

| Diametric Jaw Clearance | 2″ (51 mm) |

| Maximum Torque (At 2 rpm for short durations) | 50,000 ft lb. (67790 Nm) |

| Minimum Torque | 1,500 ft lb. (2033 Nm) |

| Maximum Speed (At Max of 10,000 ft lb.) | 18 rpm |

| Minimum Speed | 2 rpm |

| Electrical Requirements | 480 V, 3 Phase, 150 A |

| Air | 80 psi |

| Weight (Including Cabinet and Control Console) | ~13,000 lb. (~5986 Kg) |

| Length: | 84″ (213.4 cm) |

| Width: | 72″ (182.8 cm) |

| Height: | 79-1/8″ (201.6 cm) |