Description

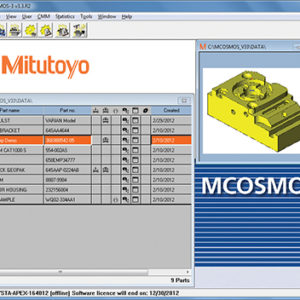

Mitutoyo America

QM-Data 200 Replacement Geometric Digital Readout, 264-140-01

Amid the constant advancement of today’s industrial world, the importance of an optical

measuring machine that allows the non-contact measurement of workpiece dimensions is

increasing, along with the growth of processing technology.

At the same time, as more rationalization and less manpower are required on the shop floor, the

factors of efficiency, speed and reliability are becoming more important with respect to

measurement.

Mitutoyo’s optical measurement data-processing systems, the QM-Data200 and vision measurement

unit answer these needs as well as supporting the all-important Quality Assurance function.

- FEATURES

Experience measurement with the QM-Data200

• High-contrast color graphic displays on the large LCD screen with LCD back light.

• One-key operation for combined measurements that are often used (circle-circle distance, etc.)

• Equipped with the measurement procedure teaching function and the measuring position navigation in Repeat mode.

• Easy measurement possible in combination with visual cross-hair alignment and automatic edge detection.

(Optoeye positioning function installed on a profile projector.)

• The AI measurement function (automatic identification of measuring item) eliminates switching between the

measurement command keys.

• The user menu function allows the user to store measurement commands or part programs to create a customized menu.

• Tolerance zone measurement of data processing result and various statistical processing for each item are possible.

• Measurement result output to “MS-Excel®” in spreadsheet (CSV) format.*

• The measurement procedure and measurement result can be saved using the USB memory.**

• Two models are available: a stand-alone type with tilt system and a flexible-arm type that can be mounted on a profile projector.***

• Measurement possible even during printout